Understanding the challenge

The HBOT chamber was to be installed inside a Grade II listed Georgian country house, built in 1792, and positioned in the corner of a small room. The project required careful consideration of the equipment’s size, weight, value, and fragility, alongside the sensitivities of working within a historic building.

Over the weekend, Bishopsgate worked closely with Elaine, sharing photographs and videos of the site, discussing access routes, unloading options, and potential risks. This early collaboration allowed a safe and workable plan to take shape before the equipment had even arrived in the UK.

Planning for success

Using technical drawings and detailed site measurements, Bishopsgate developed multiple delivery and installation methods. A site survey followed, supported by a full Risk Assessment and Method Statement (RAMS), to ensure a right-first-time approach where tolerances were tight and the surroundings irreplaceable.

A preferred method was agreed upon, allowing specialist handling and installation to be coordinated alongside the arrival of the air freight. This helped Elaine regain control and confidence.

When plans change

On Friday morning, when the consignment arrived in the UK and was delivered to Bishopsgate’s London Warehouse, an issue was immediately identified: only a pallet of accessories had arrived; the main HBOT chamber was still at Heathrow Cargo.

Janusz, Bishopsgate’s London Depot Manager, investigated further. After a series of calls and emails, it was confirmed later that afternoon that the main crate was still at Heathrow Cargo.

Rather than wait until the following week, Bishopsgate acted immediately. That same evening, a crew was dispatched to Heathrow. With the support of the US shipper’s UK-based agent, the necessary collection note was obtained, and the HBOT chamber was retrieved directly from the cargo warehouse. The large crate filled the HGV bulkhead and was transported to Bishopsgate’s Park Royal warehouse, where it was consolidated with the accessories, ready for the following morning.

Delivery and installation

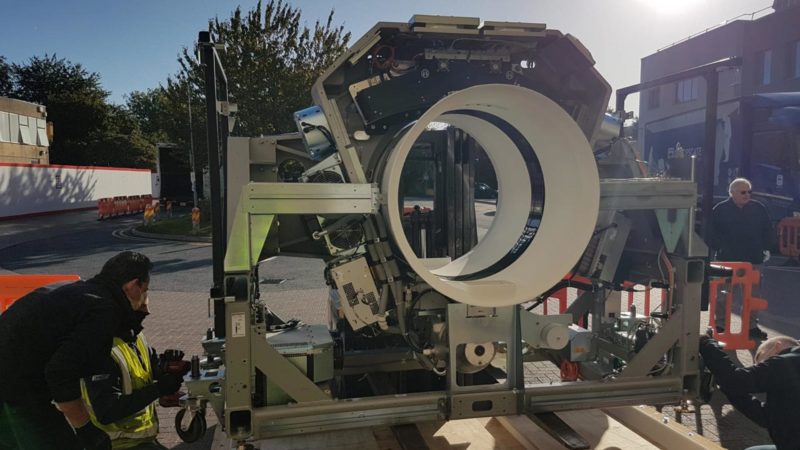

Early on Saturday, a five-person Bishopsgate team, supported by a truck-mounted crane and specialist personnel, completed the delivery and installation exactly as planned. Finishing before 11 am to meet the client’s on-site requirements.

A trusted outcome

Elaine messaged the following day:

“Tim, just to say a very BIG thank you. I still can’t quite believe how it all came together in the end.”

Reflecting on the project, Tim commented that while this was, in many ways, another day in the office for Bishopsgate, what made it particularly successful was the trust, respect, and collaboration throughout the process.

From the first call on a Friday evening to a successful installation just eight days later, the project was driven by trust, collaboration, and a solution-focused approach. A clear example of how Bishopsgate supports complex, time-critical installations from start to finish.

Learn how we can help you with your challenges

Our services